ROTARY HEAT EXCHANGERS – GENERAL INFORMATION

Frost resistant from -15°C and above temperatures at airflow from 1000 m3/h up to 150,000 m3/h thanks to movable sensitivity mass with different types of coatings. All these advantages give the possibility to install into AHUS for different applications: domestic, commercial or industrial. Range of solutions for aggressive, high thermal environments and cold weather regions. Available in customized frame size and different widths.

MAXIMUM EFFICIENCY

rotary heat exchanger advantages

Airflow

Maximum efficiency

Frost resistant

ErP 2016-2018 Compliant

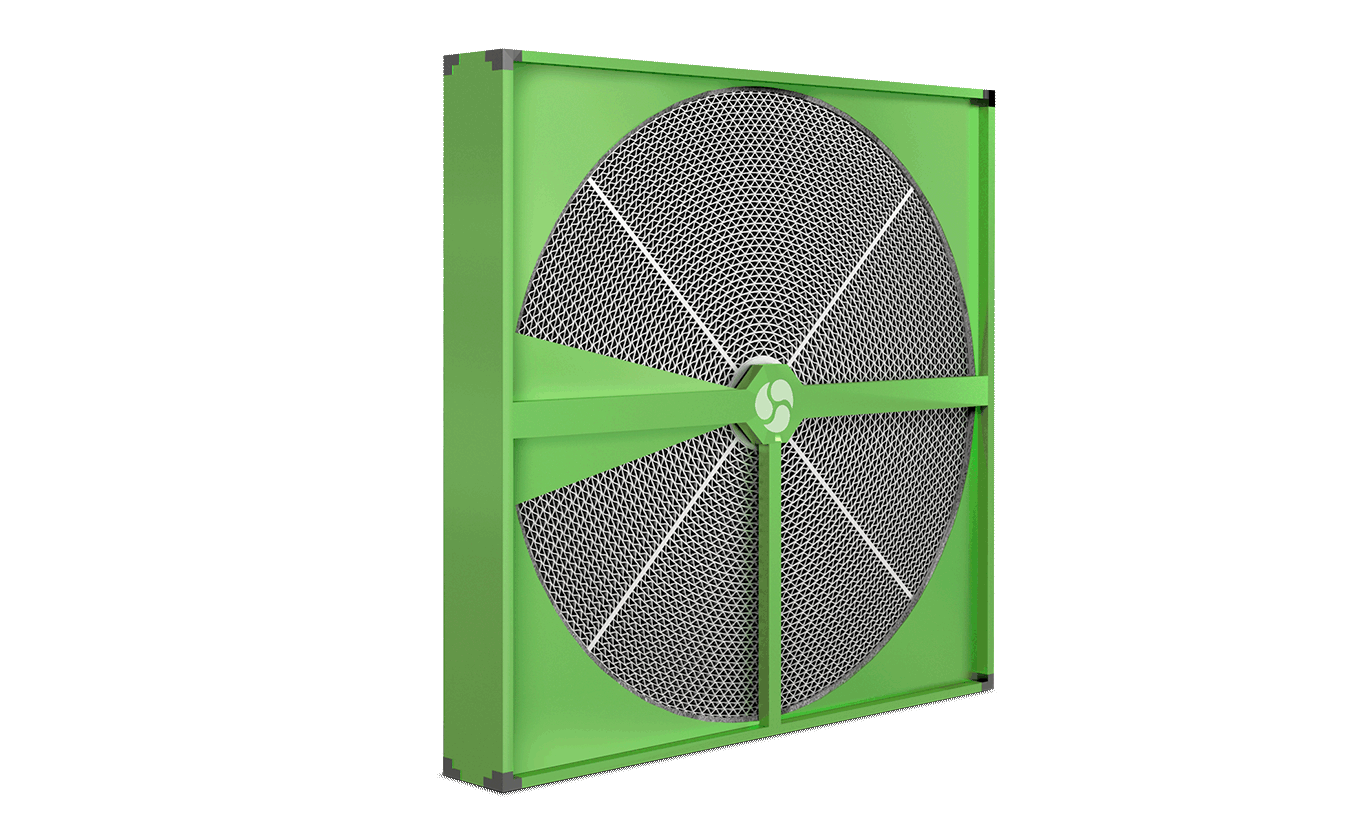

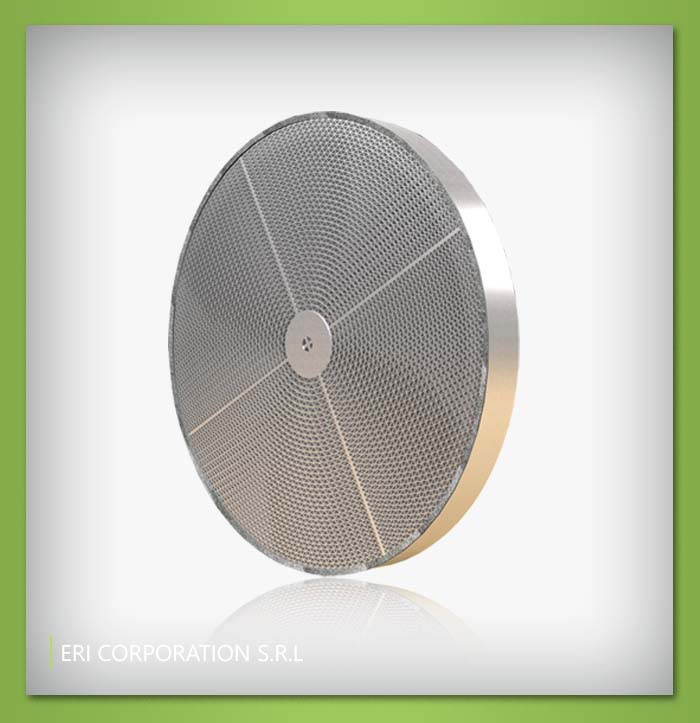

ROTARY HEAT EXCHANGER 3D MODEL

CONSTRUCTION

Layers

Rotary heat exchanger consists of two foil layers: totally flat and corrugated.

Foil thickness

To reach maximum efficiency and be suitable for cleaning standard thickness is available from 55 microns up to 70 microns.

Materials

Big range of thermal wheel materials & treatments, casing construction gives the possibility to produce rotary exchanger for any kind of applications.

Stability

Thanks to our construction our rotary heat exchanger is resistant for all mechanical damages and suitable for aggressive environments.

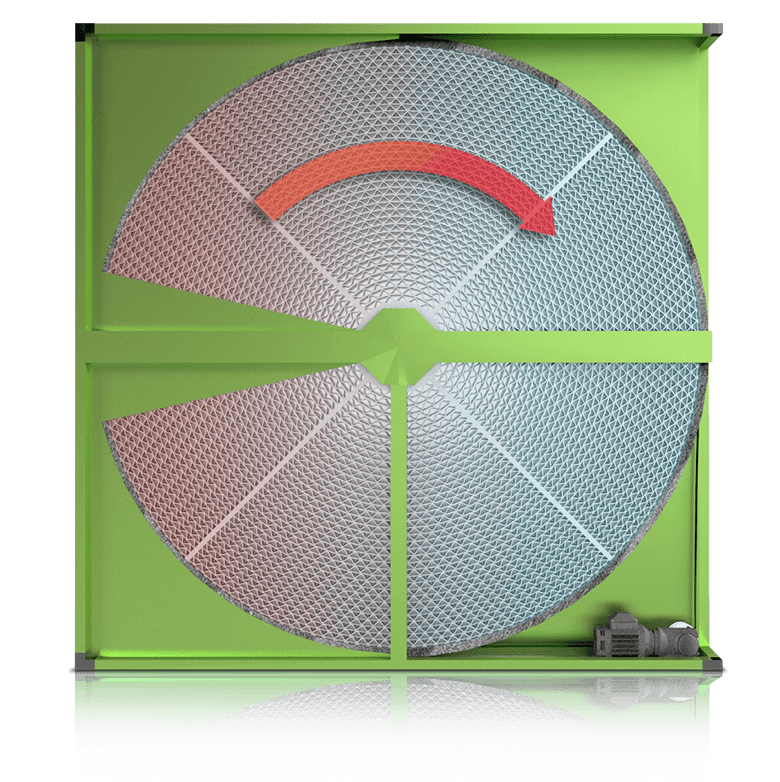

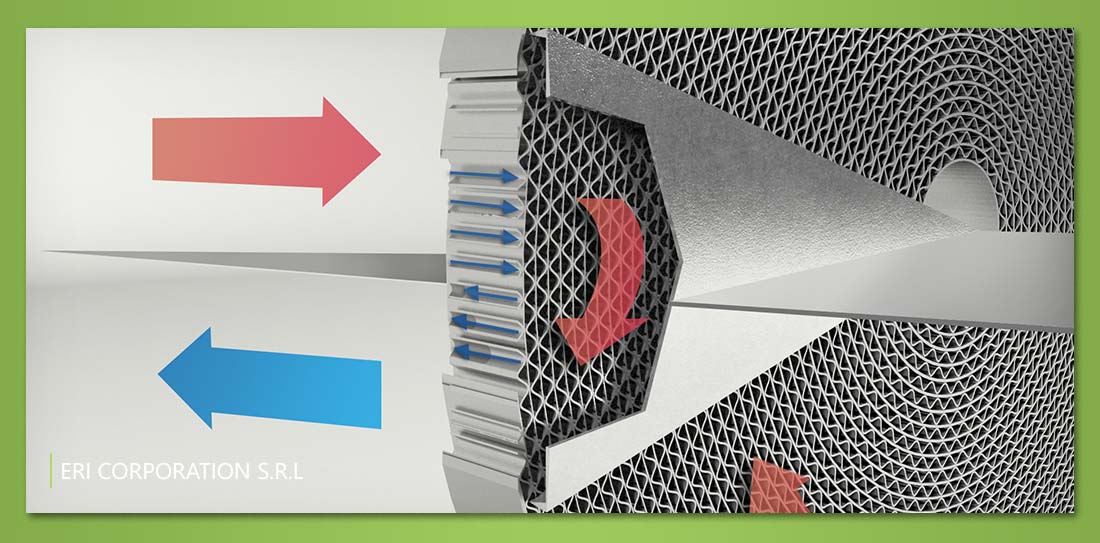

ROTARY HEAT EXCHANGER WORKING PRINCIPLE

Cooling down and warming up the foil arising by air that flows between these two layers and during rotating process of heat exchanger part, the rotary heat exchanger mass is heated or cooled by air. Heating or cooling process will take place when channels replacing and when the opposite side is entering.

CASING

Rotary heat exchanger’s casing can be constructed from aluminium profile or galvanized steel by personal request. All products can be in either galvanized or painted casings, that protect heat exchanger from corrosion. Stainless steel casings available on request.

Wheel Only

Standard casing

CASING WITH INSULATION

ROTARY HEAT EXCHANGER THERMAL WHEEL

Wheel width (200 mm, 250 mm, 400 mm), wave height (1.4 mm; 1.6 mm; 1.8 mm; 2.0 mm; 2.5 mm).

Condensation aluminum wheel

The condensation rotor is made of aluminium structure and above the dew point does not transmit humidity. This is perfect for DEC applications or standard heat recovery units.

Epoxy coated aluminum wheel

In presence of a high demanding condition, or corrosive air, we recommend to use this coated rotor, suitable against marine corrosion and with a special matrix the perfect solution for DEC equipment, paint booths, ships and coastal regions.

Enthalpy wheel

Enthalpy wheel has a Hygroscopic coating, and can adsorb and release partially humidity. Exchangers with enthalpy wheel are optimal to recover in transitional periods and in the winter time heat and humidity.

Sorption wheel

Desiccant wheel to transfer sensible and latent heat energy. Coated aluminium matrix for the transmission of moisture in winter and in summer.

ANTIBACTERIAL TREATMENT

Our treated aluminium heat exchanger, made with epoxy construction offers unmatched corrosion resistance and ensure corrosion resistance to salt water and longer equipment life.

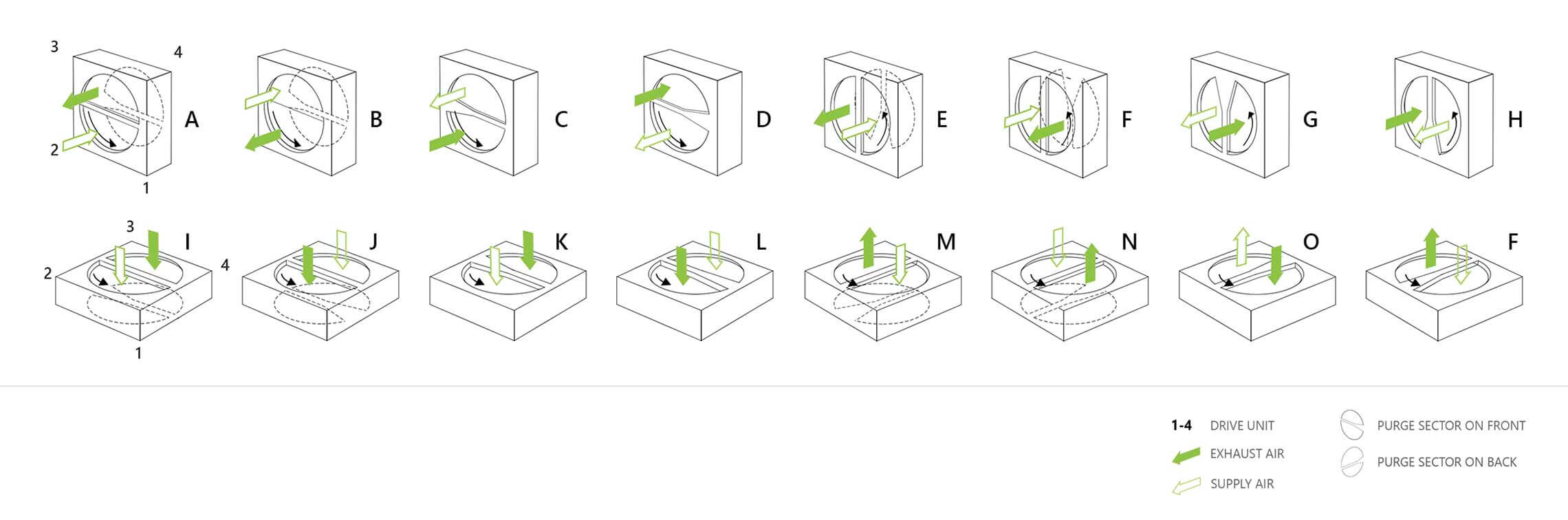

PURGE SECTOR

It possible to construct a purge sector on the cross beam of the rotor. The presence of the purge sector allows to clean the rotor channels before the fresh air area will pass through it from waist air. Thanks to this feature, cross contamination in the rotor is minimized. This sector is active only when the airflows are opposite to each other and according to working conditions.

BELT TYPES

Depending on the size of the rotor two types of the drive belt are used. A round V-belt which is coupled by means of welding or metal clip is applied to the rotor of the size of Ø 2000 mm. A trapezoidal V-belt with perforations which is coupled in a loop by means of a metal clip is applied to the rotors with a diameter greater than Ø 2000 mm.

LEAKAGE

Leakage means that recirculating air is supplied instead of fresh air. Exists an opinion that the main disadvantage of rotary heat exchanger is an air leakage through the seals between airflows. It is obvious that with increasing degree of regeneration and hence, an increase in the size of the heat exchanger leakage problem will intensify. But rotary heat exchanger developed by ERI Corporation characterized with leak tightness. Technologies that we use reduce leakage to minimum and save costs and energy.

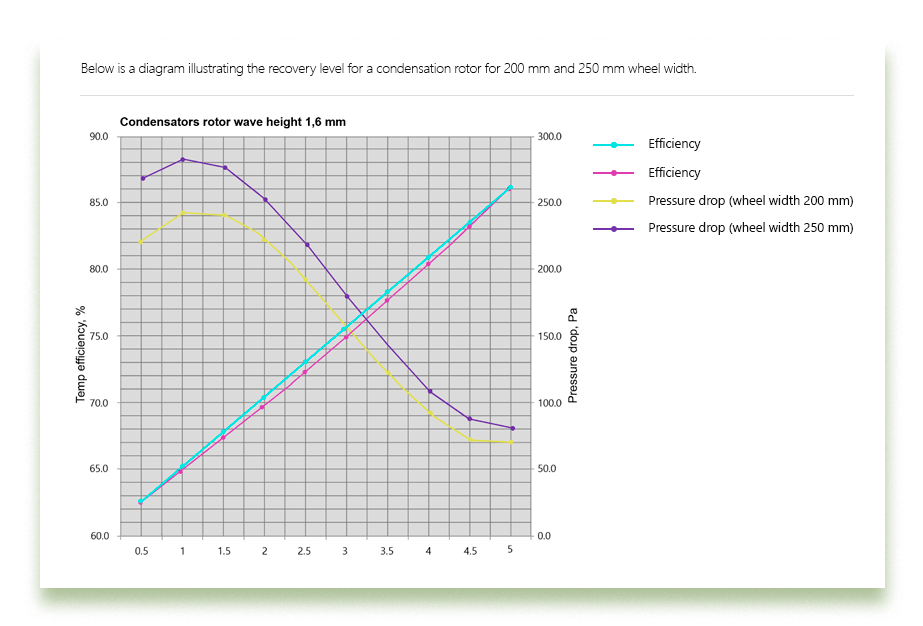

ROTARY HEAT EXCHANGER EFFICIENCY AND PRESSURE DROP

Rotor size and height is main cases that influence to the efficiency and will be increase by using smaller distance. ERI Corporation offer five different well-heights: 1.4; 1.6; 1.8; 2.0; 2.5 mm. The pressure drop will be increased accordingly. Condensation can occur, and drain-pan is consequently recommended.

EFFICIENCY DIAGRAM

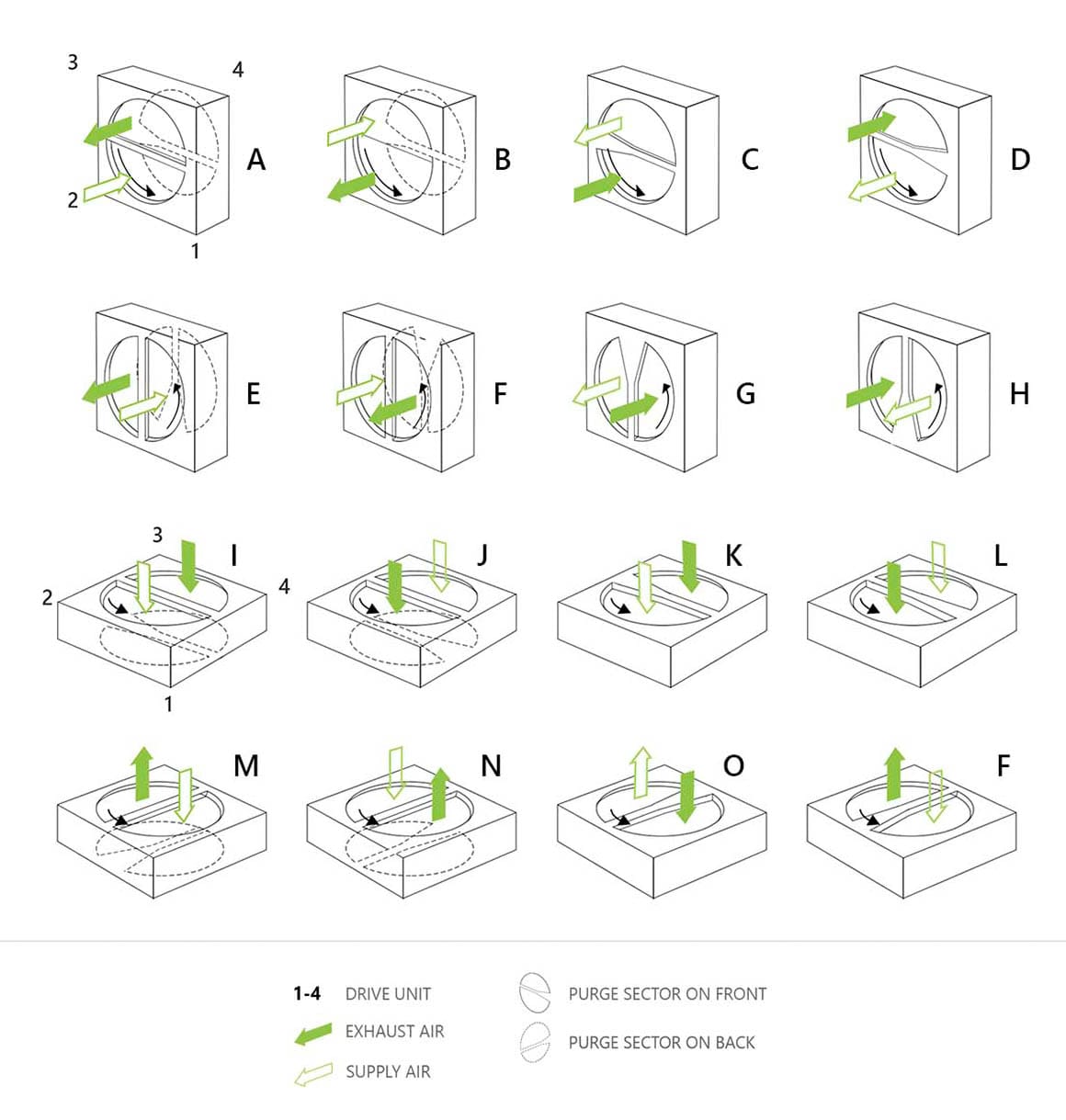

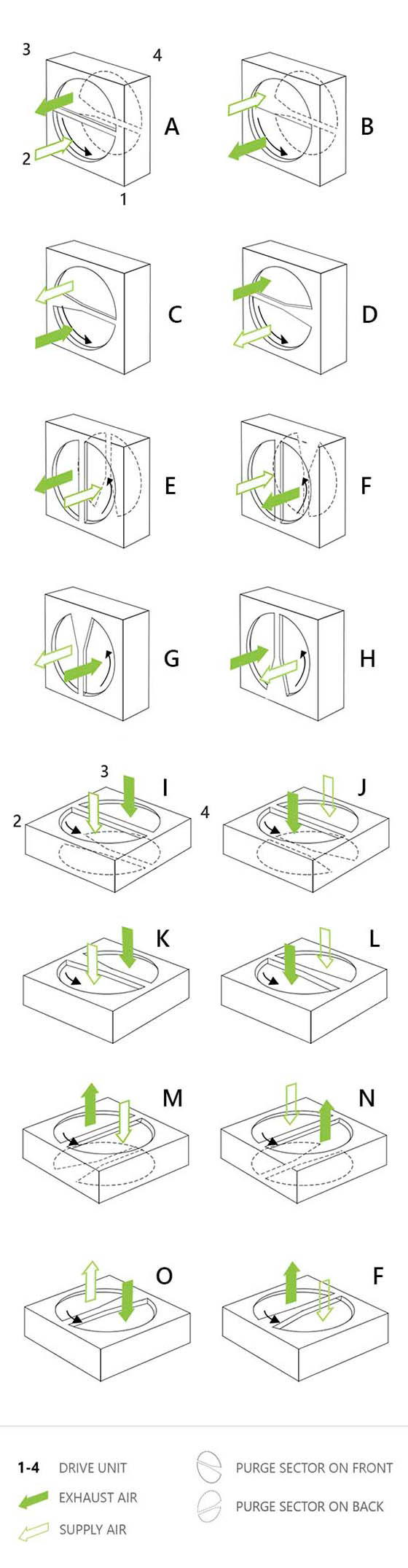

MOTOR POSITIONS

FREQUENCY CONVERTER

In order to achieve the best possible efficiency, we offer for every rotor the right and most suitable frequency converter. Thanks to the patented design of the rotor industry controller and modern manufacturing, it is built for a 10-year life-time without maintenance. The new features guarantee a 100% expectation match and with a field failure rate of less than 1 in 10,000, the new series inverter will outperform all other inverters long after it has been implemented.

OPTIONS

- Motor protection

- Programmable cleaning cycle

- Error messages

- Control terminal board with memorized parameters (patented)

- Fast CPU

- Low noise technology (patented)

- Online-tuning (patented)

- Integrated security in accordance with EN954-1

- Communication with modbus available

SPARE PARTS

Every spare part can be delivered on request within few days in small or bigger quantities and is available in our warehouse.

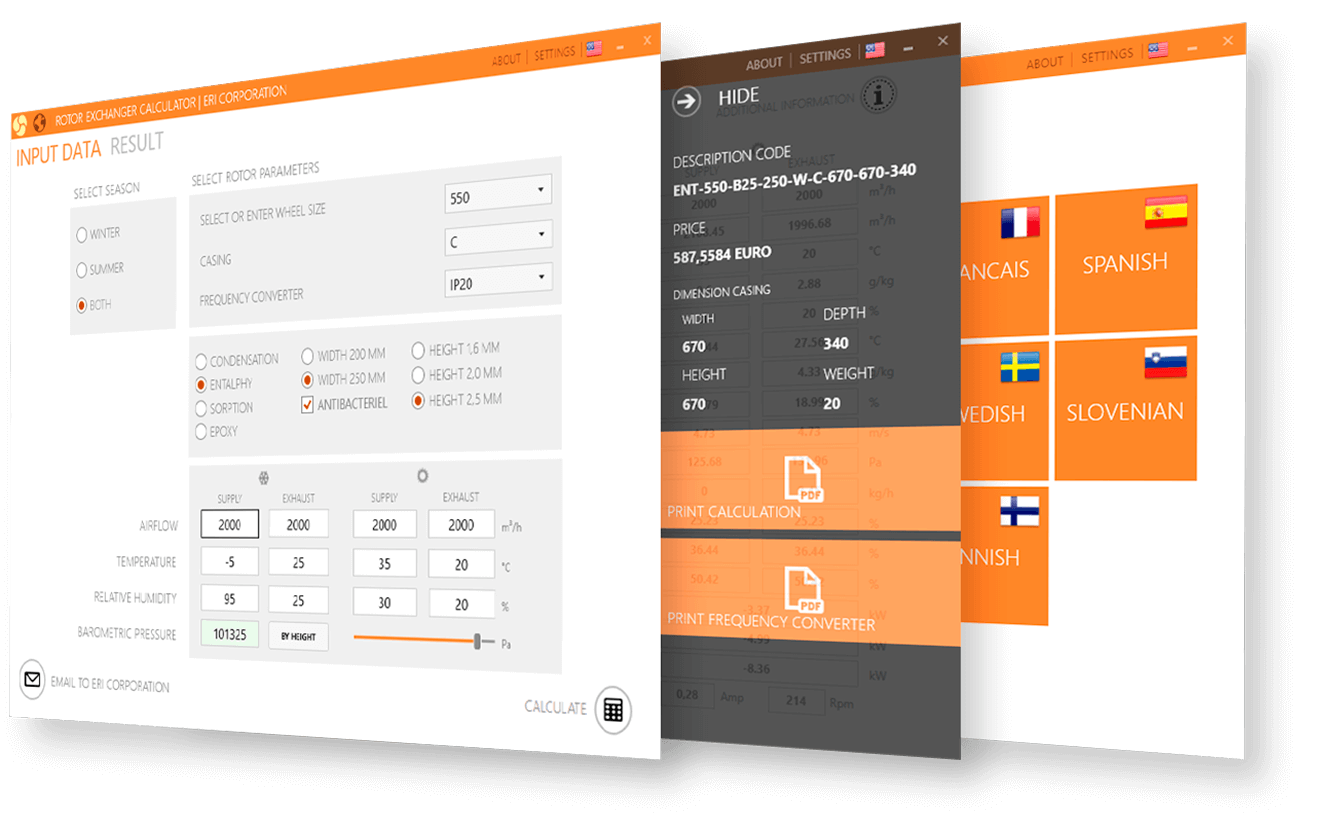

ROTARY HEAT EXCHANGER SELECTION SOFTWARE

ERI Corporation developed a special calculation program that let you select a rotary heat exchanger model in simple and understandable for every user way. This software containing all necessary characteristics to make a correct choice. For our partners, we have developed special tools to integrate through API our dll in their system. You can download the program here:

Download selection softwareHEAT TERMINOLOGY

Sensible heat

Sensible heat is an increasing or removing heat of the object. Heat that causes a change in temperature in an object is called sensible heat.

Latent heat

State of all nature substances is changeable. For example, ice can become water and then water can become vapor. That is means that solids go to liquids, and then go to gases. But all this changes of states is called latent heat.

The heat that was added but not change the state called latent heat, because it doesn’t influence to substance temperature. For example, if you add some heat to water while it boiling (100°C), the temperature will not increase, but water will be keeping boiling.

Having considered these examples, we got the understanding why cooling systems use refrigerant and why for defining a unit's cooling capacity was decided to use terms 'total capacity' and 'sensible capacity'.

Sensible heat is the heat due to temperature change and latent heat is the heat due to chase change in phase of the water content in the air.

ENG

ENG DEUTSCH

DEUTSCH ITALIANO

ITALIANO